|

|

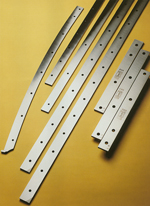

| The Industrial Knife Company

has a shear knife for every metal cutting job. We specialize in tailoring a

knife for your specific job. Below are the two most commonly used materials we

use in our shear blades: A) AISI D-2 high-carbon, high-chrome air hardening tool steel. D-2 HcHc has 12-14% chromium material and is designed for maximum number of cuts on a mechanical shear of up to, and including, 1/4" mild steel capacity. It can also be used on hydraulic shears of up to, and including, 3/8" mild steel. When cutting stainless steel, reduce the above capacity limits by 50%. B) A modified H-13 tool steel is used for shearing metal in excess of 1/4" thick mild steel. This grade can also be used when a customer does not require the long life of our D-2 HcHc steel, but wants something better than a standard carbon tool steel. |

All of our shear blades are

precision made and heat treated in the most modern furnaces. We carefully

inspect all knives before shipping them to our customers. The Industrial Knife Company's sales department can determine the right shear knife for your operation given the following information: 1) Maximum thickness to be sheared. 2) Description of material to be sheared. 3) Make and model of the machine. |

SPECIFICATION WORKSHEET FOR METAL CUTTING SHEAR BLADES

| FOUR EDGE FIGURE #1 |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| TWO EDGE FIGURE #2 |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SINGLE EDGE FIGURE #3 |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Industrial Knife Company also offers a high quality

state-of-the-art resharpening service. All of our knives are reground to the

same exacting tolerances as new knives. This insures quality cuts and maintains

a high level of production. Our computer controlled German-made grinding

machines, along with our experienced operators, allow us to maintain the

following tolerances: If you demand maximum knife life and shearing quality, use Industrial Knife Company for your resharpening needs. Click HERE for more information of our services. |

|

INDUSTRIAL KNIFE

COMPANY, INC. 16000 Trade Zone Avenue Upper Marlboro, Maryland 20774 (301) 390-8106 Fax (301) 390-7929 1-800-233-5016 info@industrialknife.com |